- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

ODMT liquid driven gas boosters are hydraulic driving. These boosters have convenient connection ways, high performance-price rate, high efficiency, large flow and wide range of application. They meet the requirements of various fields on high pressure and large flow of different gases.

Because of the special working condition, customers can consult our company on information about boosters with larger flow and higher pressure.

*Technical Specifications:

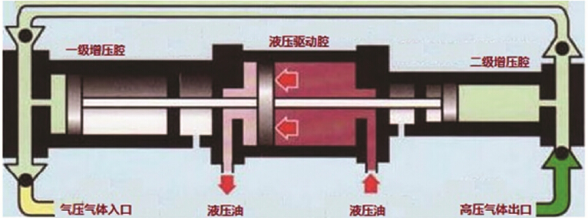

1. Pressurization process: The gas pressure operates on the piston of the booster cavity, while the hydraulic oil pressure operates on the piston of the hydraulic piston. The gas driven by the hydraulic oil pressure is compressed within the stroke and then is outputted from the high-pressure cylinder. During the process, the force on each piston at the ends remains a dynamic balance with the force on the piston of the hydraulic cylinder.

2. The booster is designed with long stroke and low frequency. The gas is cooled when it is compressed and the temperature of outlet gas isn't very high, reducing damage to the equipment.

3. Pistons: We have applied multichannel sealing and non-leakage design to ensure that the gas in the booster cavity won’t be contaminated by hydraulic oil in the driven cavity.

4. When the set pressure is reached, no additional energy is consumed, and the booster will stop working automatically. When the pressure becomes lower, the booster will start again to replenish the pressure.

5. When the level of oil tank is too low or the temperature of the oil is too high, the liquid level relay will send out signals and the system stops automatically.

6. The equipment needs 380V three-phase four-wire power supply.

7. Double-stage pressurization: Its working principle is similar to that of single-stage supercharger. Their main difference is that the pressurization cylinder tube of the second stage is smaller than that of the first stage (different pressurization ratios). The gas will be pressurized twice and turned into even higher pressure (There is cooling device between the two stages.).

*High-end application choices:

1. When the medium is inflammable gases such as oxygen, hydrogen, ethylene, etc., the system is equipped with explosion-proof motor and junction box.

2. Variable pump can provide power for this equipment. The pressurization system can change the displacement of the hydraulic pump automatically or be changed manually by operators corresponding to the change of the working pressure. Further, the flow of the booster is changed, thus realizing low pressure and mass flow, high pressure and little flow. So it has faster pressurization speed, higher working efficiency and consumes less energy.

ODMT liquid driven gas boosters are hydraulic driving. These boosters have convenient connection ways, high performance-price rate, high efficiency, large flow and wide range of application. They meet the requirements of various fields on high pressure and large flow of different gases.

Because of the special working condition, customers can consult our company on information about boosters with larger flow and higher pressure.

*Technical Specifications:

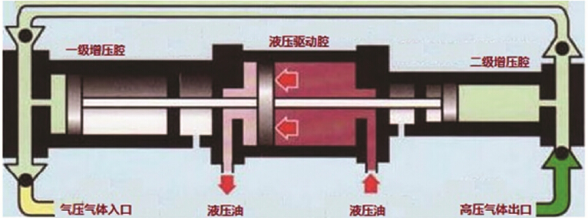

1. Pressurization process: The gas pressure operates on the piston of the booster cavity, while the hydraulic oil pressure operates on the piston of the hydraulic piston. The gas driven by the hydraulic oil pressure is compressed within the stroke and then is outputted from the high-pressure cylinder. During the process, the force on each piston at the ends remains a dynamic balance with the force on the piston of the hydraulic cylinder.

2. The booster is designed with long stroke and low frequency. The gas is cooled when it is compressed and the temperature of outlet gas isn't very high, reducing damage to the equipment.

3. Pistons: We have applied multichannel sealing and non-leakage design to ensure that the gas in the booster cavity won’t be contaminated by hydraulic oil in the driven cavity.

4. When the set pressure is reached, no additional energy is consumed, and the booster will stop working automatically. When the pressure becomes lower, the booster will start again to replenish the pressure.

5. When the level of oil tank is too low or the temperature of the oil is too high, the liquid level relay will send out signals and the system stops automatically.

6. The equipment needs 380V three-phase four-wire power supply.

7. Double-stage pressurization: Its working principle is similar to that of single-stage supercharger. Their main difference is that the pressurization cylinder tube of the second stage is smaller than that of the first stage (different pressurization ratios). The gas will be pressurized twice and turned into even higher pressure (There is cooling device between the two stages.).

*High-end application choices:

1. When the medium is inflammable gases such as oxygen, hydrogen, ethylene, etc., the system is equipped with explosion-proof motor and junction box.

2. Variable pump can provide power for this equipment. The pressurization system can change the displacement of the hydraulic pump automatically or be changed manually by operators corresponding to the change of the working pressure. Further, the flow of the booster is changed, thus realizing low pressure and mass flow, high pressure and little flow. So it has faster pressurization speed, higher working efficiency and consumes less energy.

We warmly welcome the dealers local and abroad to negotiate business and work hand in hand with us for progress.