- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

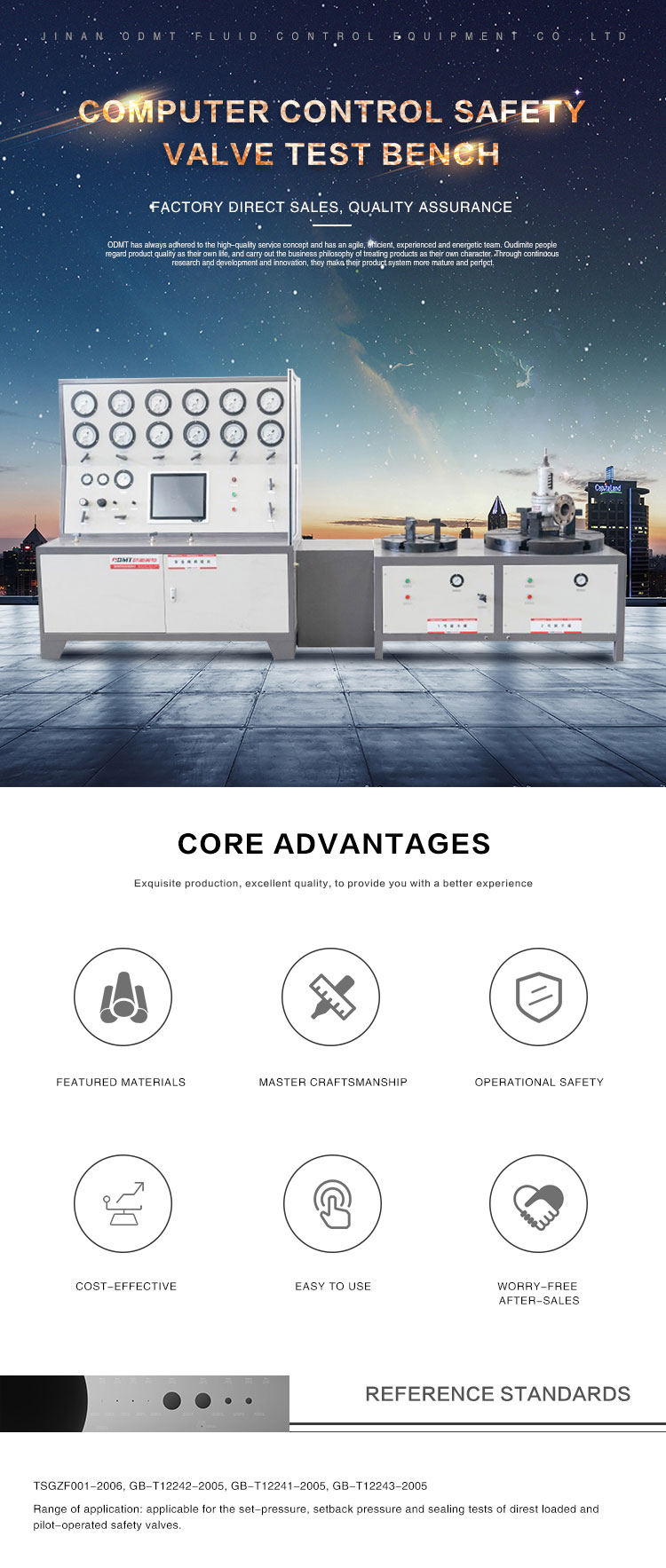

Reference Standards:.

TSGZF001-2006, GB-T12242-2005, GB-T12241-2005, GB-T12243-2005

Range of application: applicable for the set-pressure, setback pressure and sealing tests of direst loaded and pilot-operated safety valves.

Technical Parameters:

•Maximum drift diameter: DN400mm

•Maximum test pressure: 60Mpa

•Pressure test precision: pressure gauge of 0.4 grades (Users can choose a more precise one.)

•Test medium: nitrogen, compressed air or clean water (Gas liquid dual-capable one can be designed.)

Functions and Characteristics:

•The equipment has advanced design principle. It uses pneumo-hydraulic booster pump as its clamping pressure source and air driven gas booster pump as its test pressure source. A gas cylinder is equipped, which enables the test to be conducted continuously.

•The test pressure is adjustable and the process of pressurization is stable.

•Clamping pressure source and test pressure source can use imported booster pumps from America or Germany, which have a wide range of output pressure.

•All the manual high pressure valves, pipe fittings and connectors are imported ones, which guarantee their pressure levels, safety and reliability. Most gas and liquid media are available.

MAQ-400 /48BA

Functions and Characteristics:

•Maximum drift diameter: DN400mm

•Maximum test pressure: 48Mpa

•Pneumatic control hydraulic clamping device is adopted. Clamping force is adjustable. The equipped pressure gauge displays the corresponding clamping force and provides a comparison table between the pressure and the clamping force, which facilitates operators to choose appropriate lamping force according to the safety valve calibration pressure and the drift diameter.

•All the valves, pipe fittings and connectors are made of stainless steel.

•The test is operated manually and operators record the data.

•The system includes two test and calibration tables. One is equipped with two clamping devices. There are totally three clamping devices: one is for safety valves of DN15-DN100; one is for safety valves of DN100-DN200; one is for safety valves of DN200-DN400.

•Various test tools are equipped to meet the needs of customers on different kinds of safety valves.

Reference Standards:.

TSGZF001-2006, GB-T12242-2005, GB-T12241-2005, GB-T12243-2005

Range of application: applicable for the set-pressure, setback pressure and sealing tests of direst loaded and pilot-operated safety valves.

Technical Parameters:

•Maximum drift diameter: DN400mm

•Maximum test pressure: 60Mpa

•Pressure test precision: pressure gauge of 0.4 grades (Users can choose a more precise one.)

•Test medium: nitrogen, compressed air or clean water (Gas liquid dual-capable one can be designed.)

Functions and Characteristics:

•The equipment has advanced design principle. It uses pneumo-hydraulic booster pump as its clamping pressure source and air driven gas booster pump as its test pressure source. A gas cylinder is equipped, which enables the test to be conducted continuously.

•The test pressure is adjustable and the process of pressurization is stable.

•Clamping pressure source and test pressure source can use imported booster pumps from America or Germany, which have a wide range of output pressure.

•All the manual high pressure valves, pipe fittings and connectors are imported ones, which guarantee their pressure levels, safety and reliability. Most gas and liquid media are available.

MAQ-400 /48BA

Functions and Characteristics:

•Maximum drift diameter: DN400mm

•Maximum test pressure: 48Mpa

•Pneumatic control hydraulic clamping device is adopted. Clamping force is adjustable. The equipped pressure gauge displays the corresponding clamping force and provides a comparison table between the pressure and the clamping force, which facilitates operators to choose appropriate lamping force according to the safety valve calibration pressure and the drift diameter.

•All the valves, pipe fittings and connectors are made of stainless steel.

•The test is operated manually and operators record the data.

•The system includes two test and calibration tables. One is equipped with two clamping devices. There are totally three clamping devices: one is for safety valves of DN15-DN100; one is for safety valves of DN100-DN200; one is for safety valves of DN200-DN400.

•Various test tools are equipped to meet the needs of customers on different kinds of safety valves.

We warmly welcome the dealers local and abroad to negotiate business and work hand in hand with us for progress.