- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

Technical Parameters:

• Type: pneumatic proportional control system

• Test medium: air or nitrogen

• Test pressure: designed according to customers’ requirements

• Number of the test pieces: designed according to customers’ requirements; each pressure gauge can be controlled separately and is equipped with special quick connector.

• Control mode: computer control or PLC control; Users set the test pressure and the pressure holding time through the control software programmed by Labview or the PLC software. When the test is finished, the system will stop automatically and alarms.

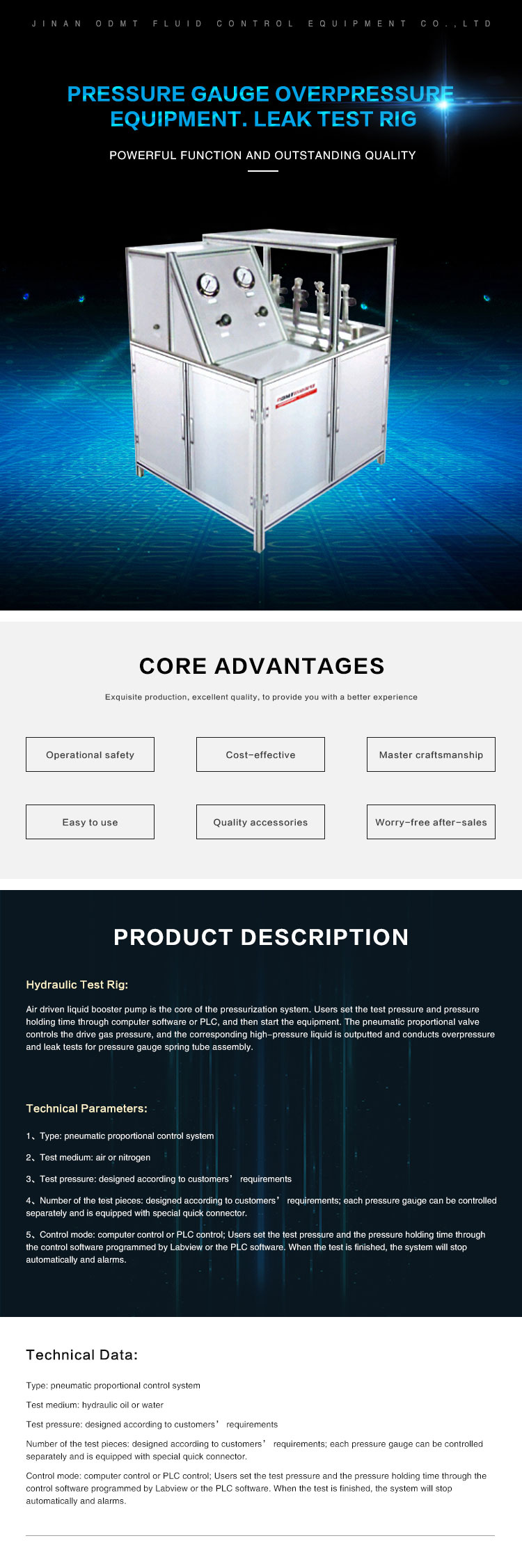

Hydraulic Test Rig:

Air driven liquid booster pump is the core of the pressurization system. Users set the test pressure and pressure holding time through computer software or PLC, and then start the equipment. The pneumatic proportional valve controls the drive gas pressure, and the corresponding high-pressure liquid is outputted and conducts overpressure and leak tests for pressure gauge spring tube assembly.

Technical Data:

• Type: pneumatic proportional control system

• Test medium: hydraulic oil or water

• Test pressure: designed according to customers’ requirements

• Number of the test pieces: designed according to customers’ requirements; each pressure gauge can be controlled separately and is equipped with special quick connector.

• Control mode: computer control or PLC control; Users set the test pressure and the pressure holding time through the control software programmed by Labview or the PLC software. When the test is finished, the system will stop automatically and alarms.

Technical Parameters:

• Type: pneumatic proportional control system

• Test medium: air or nitrogen

• Test pressure: designed according to customers’ requirements

• Number of the test pieces: designed according to customers’ requirements; each pressure gauge can be controlled separately and is equipped with special quick connector.

• Control mode: computer control or PLC control; Users set the test pressure and the pressure holding time through the control software programmed by Labview or the PLC software. When the test is finished, the system will stop automatically and alarms.

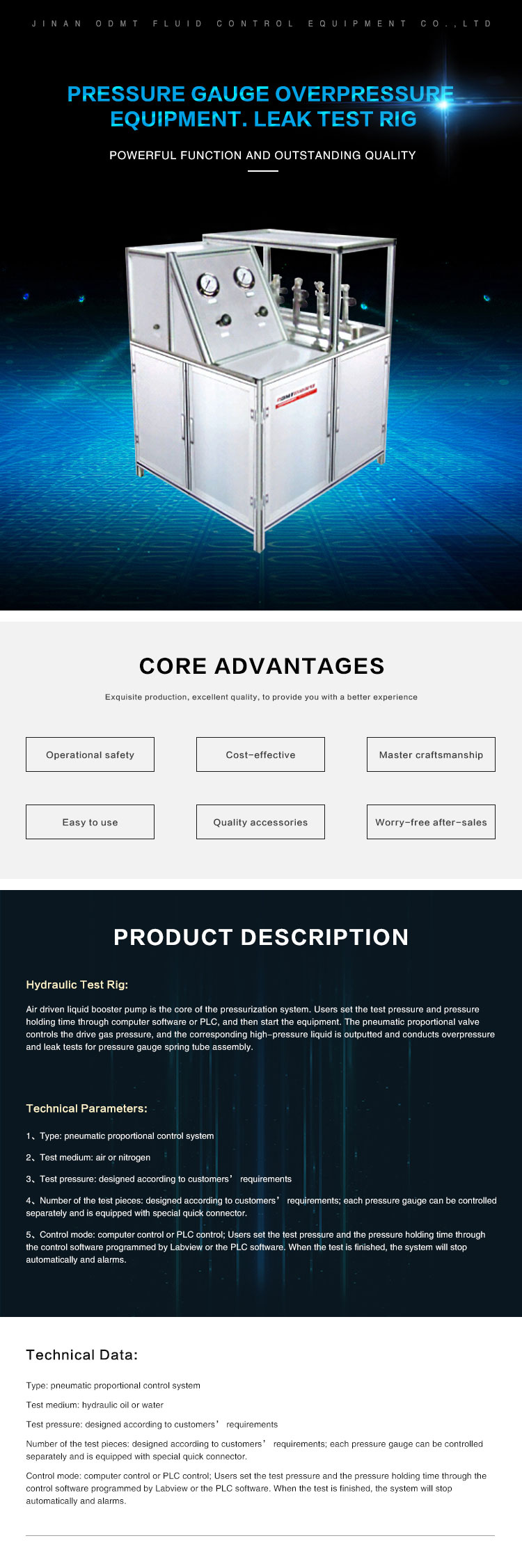

Hydraulic Test Rig:

Air driven liquid booster pump is the core of the pressurization system. Users set the test pressure and pressure holding time through computer software or PLC, and then start the equipment. The pneumatic proportional valve controls the drive gas pressure, and the corresponding high-pressure liquid is outputted and conducts overpressure and leak tests for pressure gauge spring tube assembly.

Technical Data:

• Type: pneumatic proportional control system

• Test medium: hydraulic oil or water

• Test pressure: designed according to customers’ requirements

• Number of the test pieces: designed according to customers’ requirements; each pressure gauge can be controlled separately and is equipped with special quick connector.

• Control mode: computer control or PLC control; Users set the test pressure and the pressure holding time through the control software programmed by Labview or the PLC software. When the test is finished, the system will stop automatically and alarms.

We warmly welcome the dealers local and abroad to negotiate business and work hand in hand with us for progress.