- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

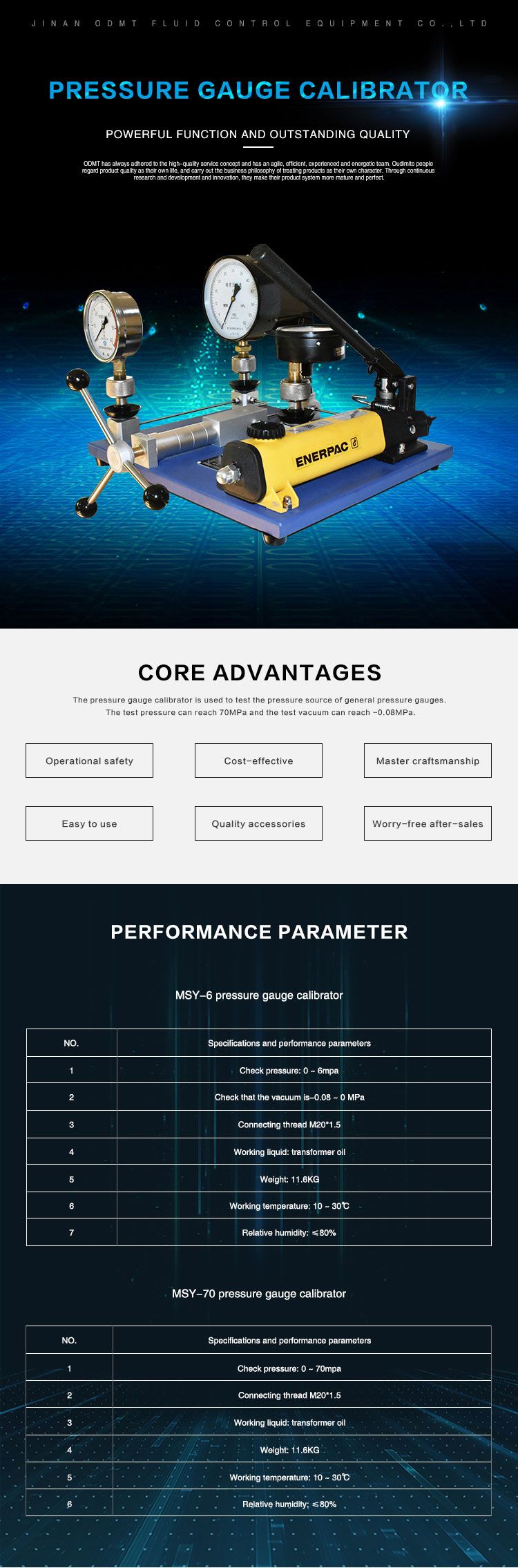

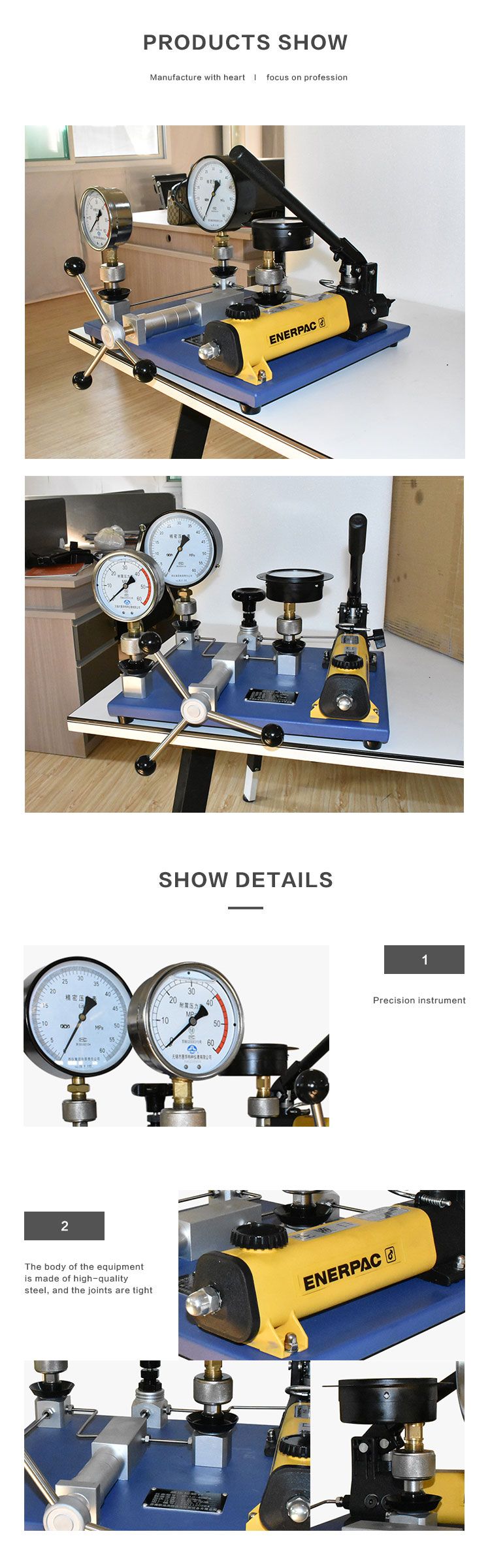

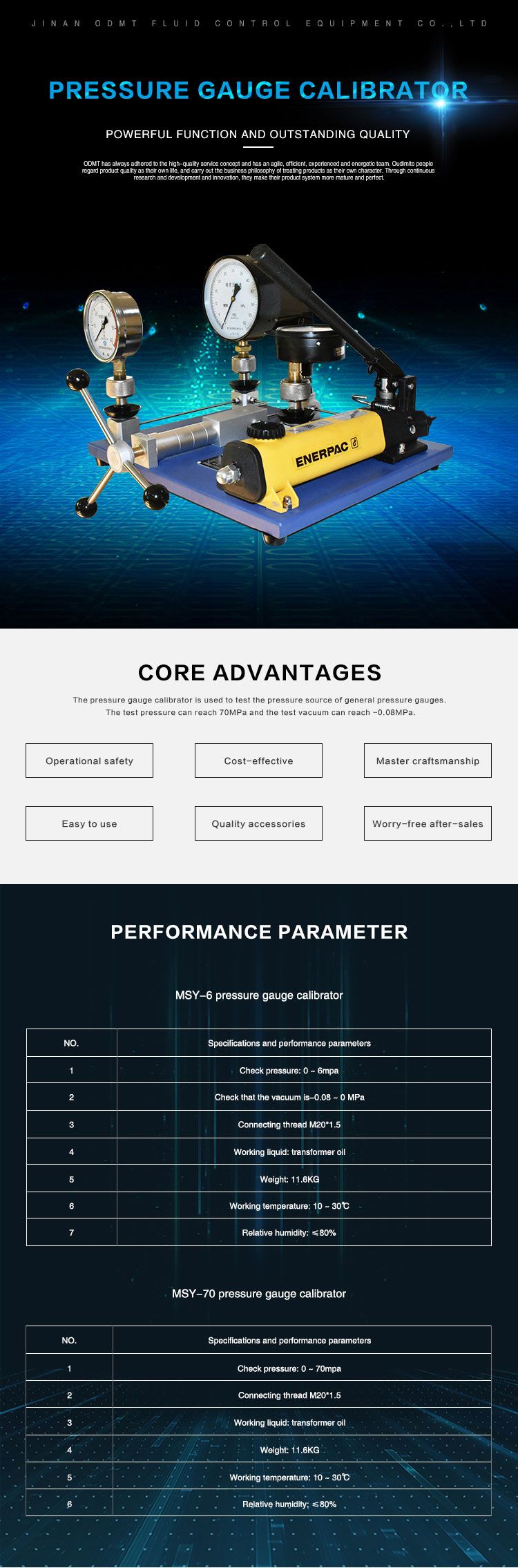

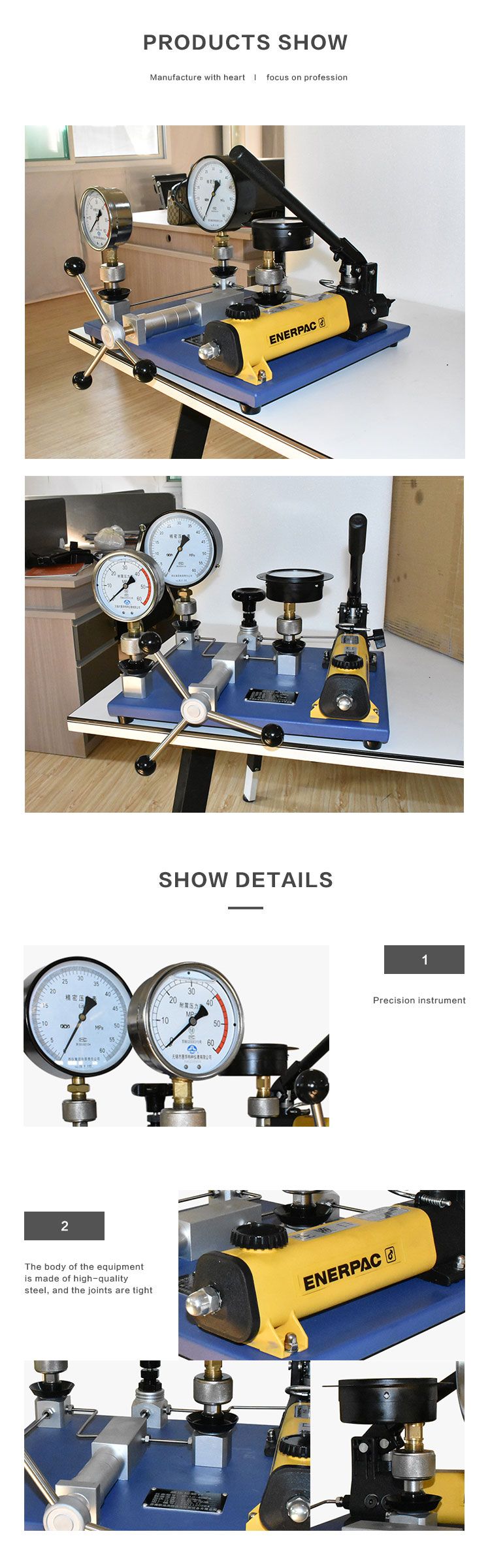

ODMT MPGC series pressure gauge calibration table is applicable for testing spring tubes (C-type tube, coil spring tube, spiral tube), etc. The calibration pressure of pneumatic calibration table is up to 15Mpa and that of hydraulic calibration table is up to 250Mpa. (Customers can consult our company on phone for more information about calibration tables with higher test pressure.)

(Pneumatic Calibration Table (0-15Mpa)) Main Characteristics:

• Users prepare calibration gas source themselves or the system is equipped with pressurization device additionally.

• Pressure regulating device with high precision controls the gas pressure of the system. This device makes it stable and precise to increase or reduce pressure during the calibration.

• All the pipelines, connectors, etc. adopt highly reliable seals, preventing the phenomena of leakage.

• The technology of quick manual connector on pressure gauge is internationally advanced. This kind of connectors has long lifespan and no leakage.

• Two pressure gauges can be tested synchronically, which can improve working efficiency.

• The calibration table has closed structure and beautiful design. It is easy to operate and maintain. It can measure the pressure, voltage and current, and outputs direct current 24V, which makes it convenient for users to test pressure sensor, digital pressure gauge or other pressure instruments.

(-0.1—1Mpa) Main Characteristics:

• Users prepare calibration gas source themselves or the system is equipped with pressurization device additionally.

•High-quality vacuum pump can be equipped for vacuum calibration.

•Pressure regulating device with high precision controls the gas pressure of the system. This device makes it stable and precise to increase or reduce pressure during the calibration.

• All the pipelines, connectors, etc. adopt highly reliable seals, preventing the phenomena of leakage.

• The technology of quick manual connector on pressure gauge is internationally advanced. This kind of connector has long lifespan and no leakage.

• Two pressure gauges can be tested synchronically, which can improve working efficiency.

• The calibration table has closed structure and beautiful design. It is easy to operate and maintain.

• It can measure the pressure, voltage and current, and outputs direct current 24V, which makes it convenient for users to test pressure sensor, digital pressure gauge or other pressure instruments.

(Hydraulic Calibration Table (0-250Mpa) Main Characteristics:

• The pressurization device has unique design, high pressure and large flow capacity.

• The servo control system regulates the pressure of the high pressure liquid. This device makes it stable and precise to increase or reduce pressure during the calibration.

• All the pipelines, connectors, etc. adopt highly reliable seals, preventing the phenomena of leakage.

• The technology of quick manual connector on pressure gauge is internationally advanced. This kind of connector has long lifespan and no leakage.

• Two pressure gauges can be tested synchronically, which can improve working efficiency.

• The calibration table has closed structure. The integrated power station facilitates the maintenance. The stainless steel countertop is neat and beautiful, and it facilitates the actual operation.

• It can measure the pressure, voltage and current, and outputs direct current 24V, which makes it convenient for users to test pressure sensor, digital pressure gauge or other pressure instruments.

ODMT MPGC series pressure gauge calibration table is applicable for testing spring tubes (C-type tube, coil spring tube, spiral tube), etc. The calibration pressure of pneumatic calibration table is up to 15Mpa and that of hydraulic calibration table is up to 250Mpa. (Customers can consult our company on phone for more information about calibration tables with higher test pressure.)

(Pneumatic Calibration Table (0-15Mpa)) Main Characteristics:

• Users prepare calibration gas source themselves or the system is equipped with pressurization device additionally.

• Pressure regulating device with high precision controls the gas pressure of the system. This device makes it stable and precise to increase or reduce pressure during the calibration.

• All the pipelines, connectors, etc. adopt highly reliable seals, preventing the phenomena of leakage.

• The technology of quick manual connector on pressure gauge is internationally advanced. This kind of connectors has long lifespan and no leakage.

• Two pressure gauges can be tested synchronically, which can improve working efficiency.

• The calibration table has closed structure and beautiful design. It is easy to operate and maintain. It can measure the pressure, voltage and current, and outputs direct current 24V, which makes it convenient for users to test pressure sensor, digital pressure gauge or other pressure instruments.

(-0.1—1Mpa) Main Characteristics:

• Users prepare calibration gas source themselves or the system is equipped with pressurization device additionally.

•High-quality vacuum pump can be equipped for vacuum calibration.

•Pressure regulating device with high precision controls the gas pressure of the system. This device makes it stable and precise to increase or reduce pressure during the calibration.

• All the pipelines, connectors, etc. adopt highly reliable seals, preventing the phenomena of leakage.

• The technology of quick manual connector on pressure gauge is internationally advanced. This kind of connector has long lifespan and no leakage.

• Two pressure gauges can be tested synchronically, which can improve working efficiency.

• The calibration table has closed structure and beautiful design. It is easy to operate and maintain.

• It can measure the pressure, voltage and current, and outputs direct current 24V, which makes it convenient for users to test pressure sensor, digital pressure gauge or other pressure instruments.

(Hydraulic Calibration Table (0-250Mpa) Main Characteristics:

• The pressurization device has unique design, high pressure and large flow capacity.

• The servo control system regulates the pressure of the high pressure liquid. This device makes it stable and precise to increase or reduce pressure during the calibration.

• All the pipelines, connectors, etc. adopt highly reliable seals, preventing the phenomena of leakage.

• The technology of quick manual connector on pressure gauge is internationally advanced. This kind of connector has long lifespan and no leakage.

• Two pressure gauges can be tested synchronically, which can improve working efficiency.

• The calibration table has closed structure. The integrated power station facilitates the maintenance. The stainless steel countertop is neat and beautiful, and it facilitates the actual operation.

• It can measure the pressure, voltage and current, and outputs direct current 24V, which makes it convenient for users to test pressure sensor, digital pressure gauge or other pressure instruments.

We warmly welcome the dealers local and abroad to negotiate business and work hand in hand with us for progress.